THE FUTURE OF BARRIER COATED PAPER PACKAGING

The revolutionary Ecosafe barrier coating machine enables to coat multiple WB barrier coatings in one pass with one operator with lowest energy consumption.

Lennart Group has more than 400 different coating combinations for achieving the best solutions for customers . Formulations are made for our customers . The multi-coating station enables us to create multi function papers by using different coating types from different manufacturers . So , our customer will enjoy ready made formulations when they have their Ecosafe Barrier Coating machine .

PICTURES

A large industrial robotic machine with various components and rollers in a spacious, well-lit factory or warehouse setting.

Industrial robotic machine with a long bar, located inside a spacious warehouse or factory.

Industrial machine with yellow protective paper wrapped around rollers.

Industrial machine with rollers and electrical components in a spacious workshop or factory setting.

Long black and beige automated machine with green accents, featuring computer monitors and various equipment, used in technology or manufacturing processes.

Industrial machine with rollers and conveyor belt moving a cardboard sheet, used for processing or packaging.

A computer screen displaying a manufacturing or processing system interface with the message 'Coater Ready' and options for quick start parameters, remote control, and configuration, with machinery in the background.

Industrial printing or manufacturing machinery in a warehouse.

Industrial printing or paper converting machines in a warehouse with metal roll feed systems and control panels.

Industrial machine with 'EcoSafeBarrier' label and a tablet on top, in a workshop setting.

A digital control panel displaying a schematic diagram of a manufacturing process, with machinery in the background.

Automated machinery for eco-friendly waste management, labeled EcoSafeBarrier, with two touchscreen control panels displaying operational parameters and safety alerts.

Eco2sheet

Eco2web

PAPER & CARTON THICKNESS

25 gsm to 1200 gsm

COATING THICKNESS

0,1 g/m2 to 60 g/m2

PAPER & CARTON WIDTH

500mm to 1200mm

PAPER ROLL DIAMETER

800mm to 1500mm

Sustainable Packaging for ALL

VIDEO’s of Eco2 Machine

PRODUCTS TO BE PLASTIC FREE WITH ECO2 MACHINE LINES

FAST FOOD PACKAGINGS

SLEEVE LABELS

FLEXIBLE PACKAGINGS

LIDS

PAPER CUPS /BOWLS

POUCHES

MEDICAL PACKAGINGS

HYGINE PACKAGINGS

A white, rectangular, pre-packaged wet wipe or cleaning wipe in a sealed plastic wrapper on a wooden surface.

Cover of a magazine titled 'dijital ve baskı 3d,' featuring advertisements for Ricoh Latex printers and a cityscape with digital billboards at sunset.

A plastic zippered bag containing rectangular white sticky notes with a textured surface, placed on a wooden surface.

A person with a tattooed arm holding a plastic bag containing a liquid with a foam head.

A plastic-wrapped printed advertisement for Sekamsan, a paper and cardboard company, featuring the slogan 'Sekamsan, Gücünüze Güç Katar!' and a bee mascot, with some small images and text at the bottom.

Stack of paper coffee cups on a wooden table.

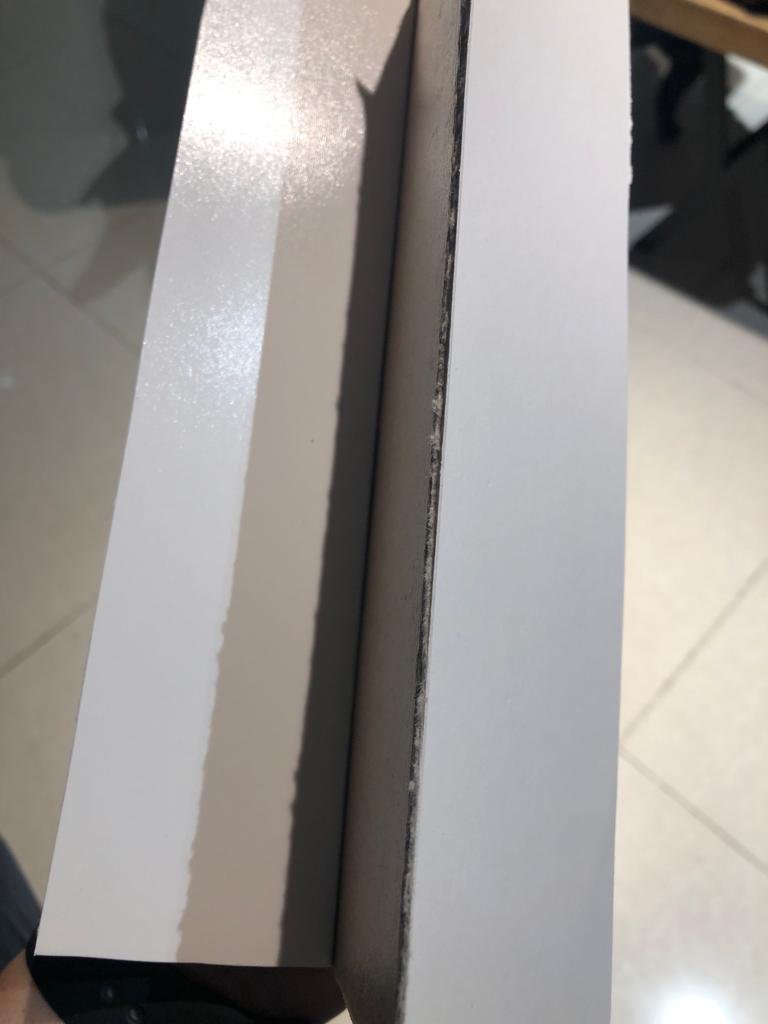

Close-up of a damaged or uneven painted wall with a crack or gap.

Close-up of a paper folder, showing the inside and outside of a folded paper or cardboard sheet on a wooden surface.

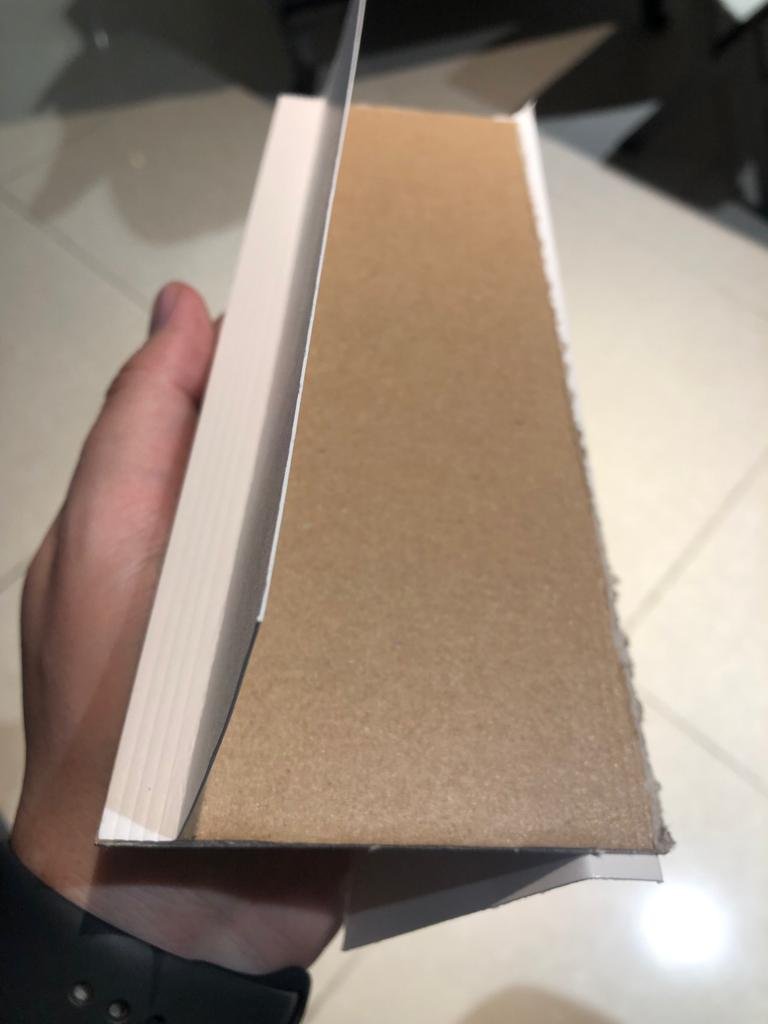

A hand holding a cardboard box with a white edge, viewed from the side.

Two clear plastic bags with food ingredients on a wooden surface, one contains uncooked spaghetti and the other contains small shell pasta.

A sealed plastic package of uncooked spaghetti pasta on a wooden surface.

A clear plastic bag of uncooked spaghetti pasta held in a person's hand.

A clear plastic bag of uncooked yellow pasta with a bowtie shape, held in front of a glass door and tiled floor.

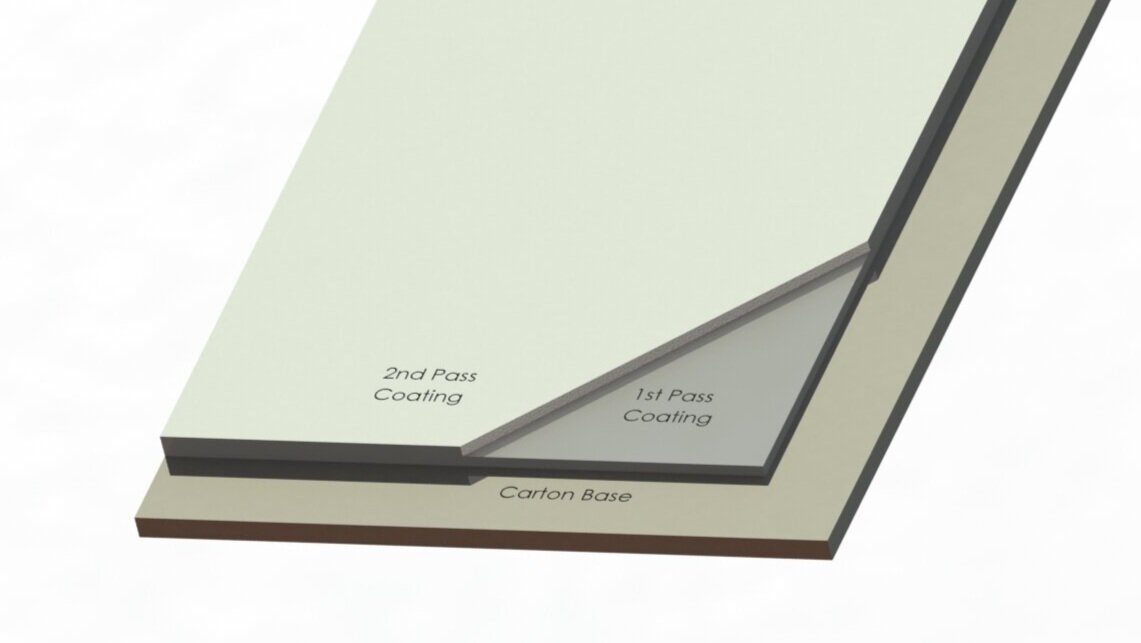

COATING LAYERS

Coating layer thicknesses are changeable depending on products and carton types . Water barrier coatings , heat sealable W.B coatings should be coated double pass coating line for excellent product quality .

Double / Triple pass coating lines will open new markets to customers . Back side coating options available .

For more information about new opportunities . Please get in touch with us .

FEATURES

ECOLOGICAL & ECONOMICAL

In growing demand for ecological packaging products. Companies face higher costs in production. Lennart Group will offer coating costs that will be lower than the non-ecological product production. Also, packaging companies will be flexible in production rather than keeping a high amount of special cartons in their stocks. “ Coat on Demand “ technology will make packaging companies coat their special cartons .

SUSTAINABLE COATINGS

Lennart Group B.V's statement is to sell sustainable products in the market. All water-based coatings have safety certifications and FDA approvals. The productions take place in Europe thanks to our suppliers. Coatings are made for our machines to work with performance.

TECHNOLOGY

Eco2Web and Eco2Sheet machines are made for coating cartons. Thanks to patented coating technology, cartons coat from 1g/m2 to 60 g/m2 with excellent surface thickness with speeds 120m/m. All models have; Industry 4.0, auto nip thickness adjustment system, special drying systems, fast material change system, auto cleaning system, moisture and coating thickness measurement system , live video view from different parts of the machine . IoTech4 state of art industry 4.0 system

SERVICE & SUPPORT

LLENNART GROUP B.V & ECOSAFE BARRIER INC have warehouses in Rotterdam - NL and USA ( Production). Critical parts have been stocked for emergency needs... Thanks to our Industry 4.0 system. If any electrical problem, our technical staff will solve it online. Coatings will be shipped from both warehouses regarding customer locations. Safety stocks will be available for each customer.

COATING SYSTEMS

Eco2Web and Eco2Sheet models use special coating units which are made for water barrier coatings. Together with the machine Lennart Group b.v supplies necessary parts to coat other coatings on the carton. In double pass systems, one set hybrid unit is given to expanding machine coating capability. The models are made on a 7/24 working basis so that coating units must have high standards.

ZERO PLASTIC MISSION

Our world is dying. We and our partners are working hard to create machines and coatings for eliminating plastics from our environment. That’s why we will keep creating new coatings to help the ecosystem. It is hard to combine all different variables to create sustainable products for the packaging market which has a long history of using plastic-based products. But it is going to change. We believe in technology that helps our planet live.

TECHNICAL DETAILS

• Patented coating/drying system .

• Auto coating thickness control (PATENT PENDING)

• Carton weight from 40 gsm to 540 gsm . Eco2Sheet (140GSM-1200GSM)

• Coat On-Demand . Speeds up to 150 meters/minute .

• Fast change-over ( Less than 3 minutes ) for different coatings.

• Auto Cleaning System (PATENT PENDING)

• Industry 4.0 and IOTech4 network accessible recipes and database.

• Auto Moisture & Coating Thickness Measurement System . ( OPTION )

• Live Camera integrated

• Integrated multi coating stations ( PATENT PENDING)

• Fully recyclable.

• Compostable ( In ideal carton types)

• Ideal for carton packaging industry.

• Eliminates Plastics / Synthetic / Thermal lamination Films .

• Competitive price compared to Plastic coatings .

• FDA - BfRXXXVI - EC NO:1935/2004 approved coatings for food and beverage packaging